Capabilities

Assets

Hamilton Adhesive Labels takes a scientific approach to manufacturing. A ‘measure and control’ philosophy is in place for every step of the process.

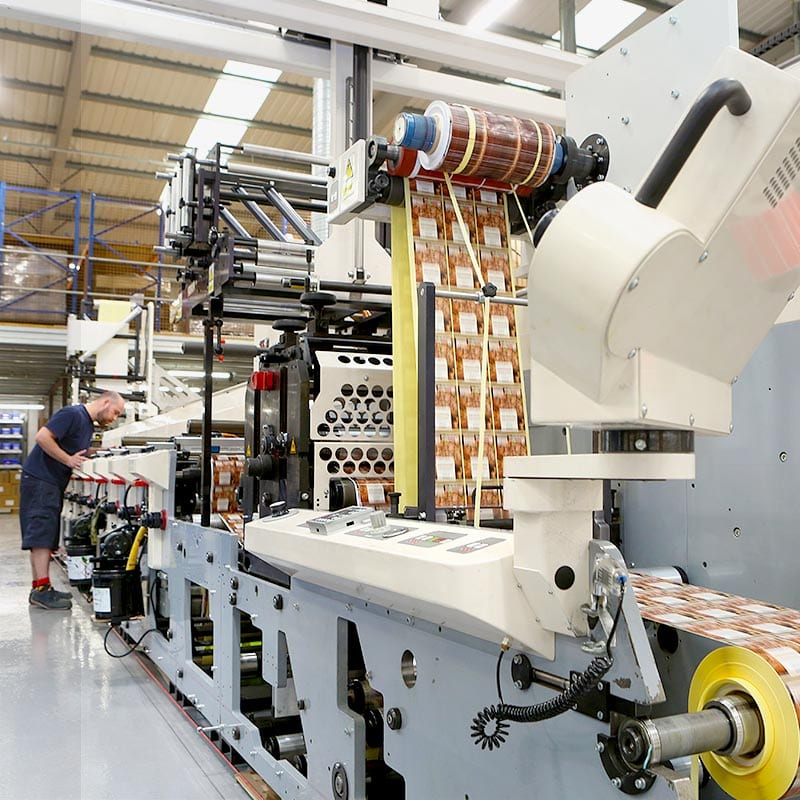

Ongoing investment in presses and staff training also ensure that the 3 MPS EF Series UV Flexo Multi Colour Printing Presses are the most efficient in the market today.

Turret rewinding with inspection ensures complete quality control and flexibility for short run jobs and a 20,000ft2 warehouse next to the press room ensures just in time manufacturing is a reality and stock holding capability is available for clients.

Systems

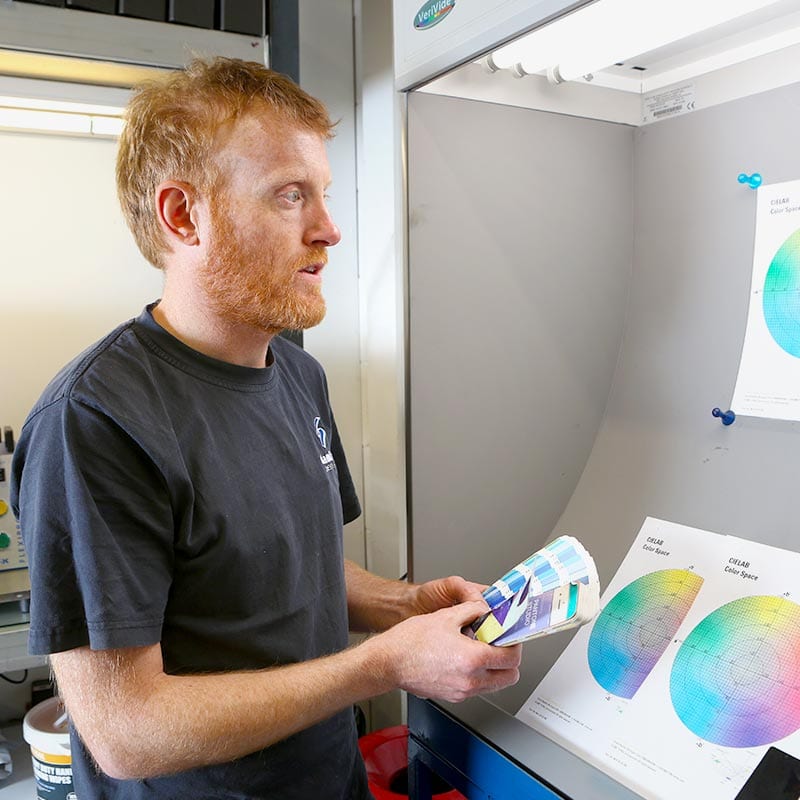

Complete benchmarking and analysis of the entire manufacturing process has been undertaken at Hamilton to ensure optimum efficiency at every stage of the process.

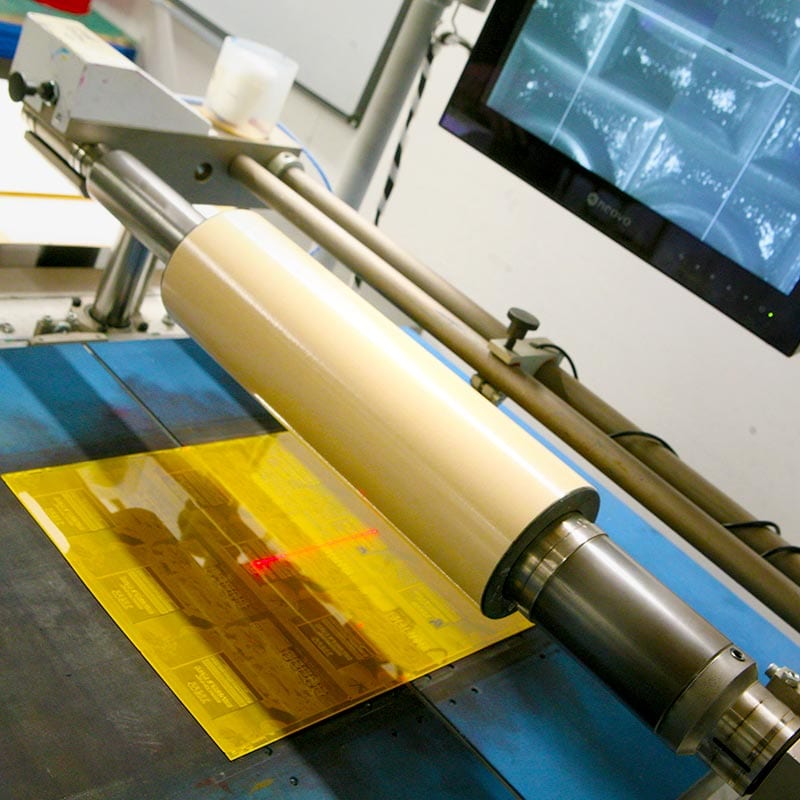

Utilising a ‘measure and control’ philosophy, from plates to inks to anilox rolls, each print variable has been assessed for its performance ensuring Hamilton only produce premium quality solutions on time, every time.

Utilising Formula 1 principles in job changeovers, the Hamilton production team have complete skill and asset flexibility to ensure performance is continually challenged and a continual improvement mindset is embedded.

BRC accredited since 2006, Hamilton regularly exceeds the requirement by investing in equipment and systems that support constant innovation and lean manufacturing techniques and principles are utilised throughout the production facility.

Service

Truly caring about our customers is core to Hamilton values. We have a total commitment to getting things right, first time and every time.

Hamilton quotations are supplied within four hours using specialist software specifically designed for the label industry and every product is allocated a unique reference number and product specification recording all criteria required for exact replication and traceability.

Repeat orders are commonly processed from receipt to production planning within minutes and status is updated at all stages.

Each job is monitored using Factory Real-Time Recording to check the productivity of each machine and the accuracy of every quote.